When we talk about building materials, "hexagonal net" may not be the first impression, but it is an indispensable star material in many engineering projects. Whether it is used for agricultural breeding or slope protection, hexagonal nets have won wide recognition for their durability and versatility.

Revealing the charm of the hexagonal net: why it is a star material in engineering construction?

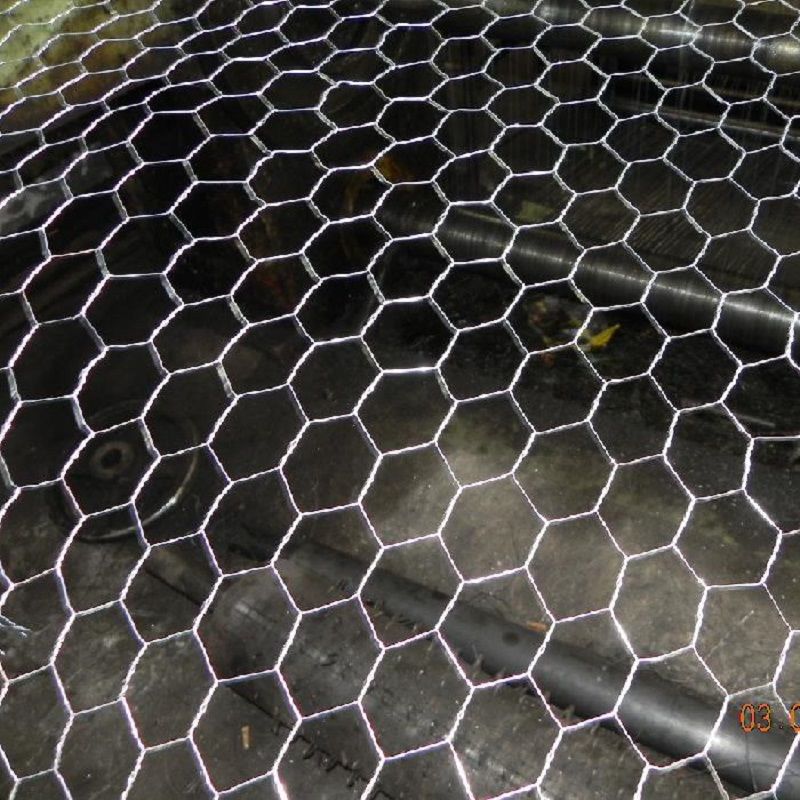

Hexagonal mesh is a mesh-like structure woven from high-strength metal wires, with excellent tensile strength and stability. Especially after special treatment (such as galvanized), its corrosion resistance and life has been significantly improved. This enables the hexagonal net to work for a long time in various harsh environments without damage.

From Farmland to Hillside: Flexible Application of Twisted Net in Multiple Scenarios

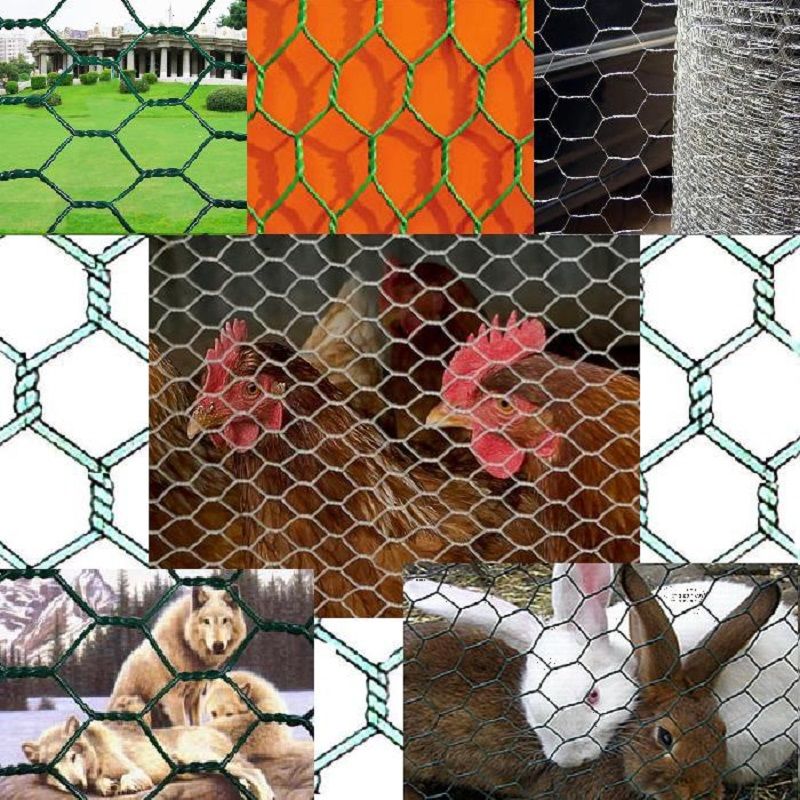

Twisted mesh is a deformed product of hexagonal mesh. On the basis of traditional hexagonal mesh, a "twisted" design is added to make it more suitable for applications that require stronger fixing ability. For example, in the field of agricultural production, it can be used to make livestock fences; and in the construction process, it can be used as part of the soil reinforcement system to prevent landslides and other problems.

details determine success or failure: how does chicken core net ensure animal safety and environmental stability

Another common type of hexagonal net is called "chicken core net", named because of its small aperture and shape similar to an egg. This network is very suitable for laying materials on the floor of the writer's poultry house, which can effectively protect the health of the young feet and maintain good clean and sanitary conditions. At the same time, it can also play a certain role in drainage to reduce the risk of disease transmission.

It is important to choose the right material: what is the difference between galvanized steel wire and other options?

In order to adapt to different use requirements and extend the service life, A variety of surface coating products have been introduced on the market. The most popular one is the coated version produced by hot dip zinc process. Compared with the ordinary bare iron version, the former has better oxidation resistance and more beautiful appearance. In addition, there are plastic coating types and so on for customers to choose and purchase suitable styles, specifications, sizes, colors and other aspects of parameter configuration schemes according to their needs. Consider clearly before placing an order for payment!

actual case sharing: see how others successfully use hexagonal net

through the feedback of some real users, we can know how they integrate these magical gadgets into all aspects of daily life to create value! For example, a farmer told that he had faced the problem of hare invasion and finally relied on the installation of a circle of strong and reliable guardrails to completely solve the old problem that had plagued him for many years. Another garden designer mentioned that he skillfully used such devices to complete the vegetation planting task on complex terrain during the implementation of a large-scale greening project, greatly improving the work efficiency and reducing the cost.

Maintenance tips: key steps to extend the service life of hexagonal nets

although this kind of product itself is very firm and reliable, it is still recommended to check and clean it regularly so as not to cause local rust and damage due to long-term exposure to wind and rain, which will affect the overall effect, poor performance or even failure and scrap. therefore, corresponding preventive measures must be taken at ordinary times ~ for example, you can gently remove dust and dirt on the surface with a brush and then spray a proper amount of antirust oil to evenly cover the blind area without leaving dead corners. To achieve the desired conservation results!